Master of Environmental Science (MSc.), ‘96, Wageningen Agricultural University, Holland.

Founder of Kilian Water, Holland & Owner of Kilian Water Ltd. Denmark, 2001

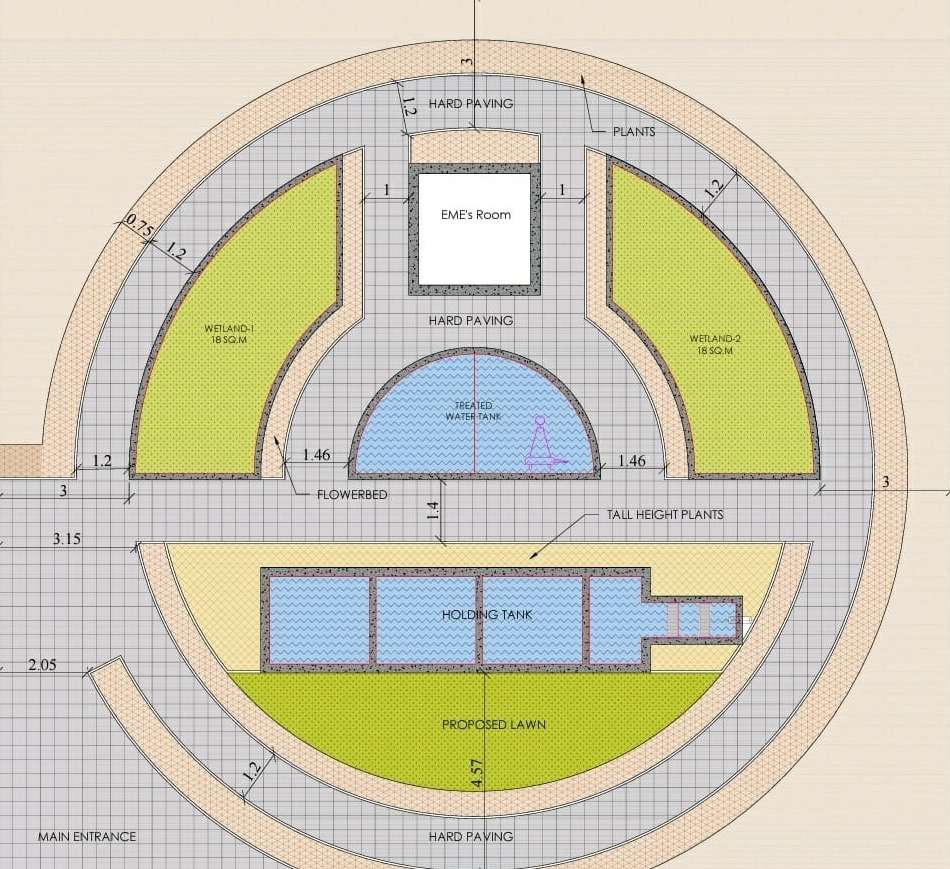

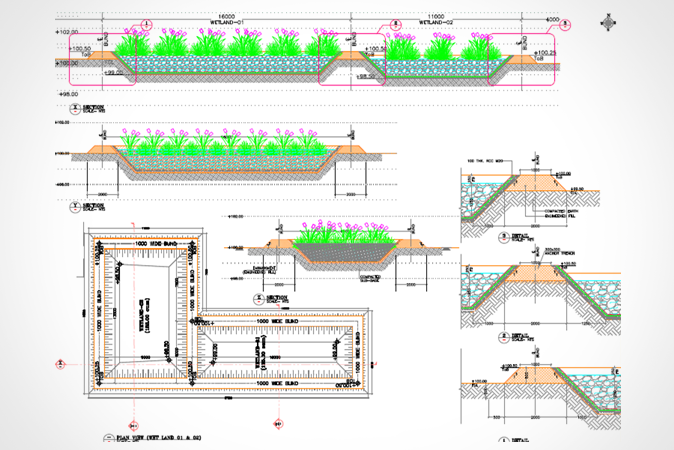

Kilian Water Ltd. belongs to the few firms in the world havingexperiencewithboth design, establishing, operation& maintenance of different types of constructedwetlands: horisontal flow, vertical flow, aerated and METlands ; depending on the local needs extra applications are added like recirculation, fosforremoval, infiltration, re-use, irrigation.

The primaryproductisconstructedwetland;secondarywillow-evaporationsystem. Since 2005 around 1000 systems are made in Denmark, Sweden, Bosnia, India, varyingfrom 2,5 – 1000 PE. The systemstreat water from a wide range of sources;households, industry, villages, campings and restaurants.

To contribute to the improvement and development of the wetlands, Kilian Water Ltd. workstogetherwithknowledge-based-institutes like Technologial Institute and Aarhus University. Kilian Water has been partner in severalDanish and EuropeanResearchprojects like SWINGS, HIGHWET and iMETland; fx was SWINGS an Indian-European cooperation project, where Kilian was responsible for the design at AMU (2013-2015).

Mr. Kilian has more than 20 years experience in the field of wastewater treatment. He works whole-heartedly with an open mind and with practical hands-on-work guiding both private persons, municipalities and entrepreneurs.